How Induction Heating Drives Innovation in the Automotive Industry

May 28, 2025

Induction heating has become an essential and highly efficient technology across various stages of automotive manufacturing. Known for its precision and speed, this method outperforms traditional heating techniques by enabling faster production cycles, improved product quality, and a reduced environmental footprint.

The automotive industry—constantly striving for innovation and sustainability—provides a strong foundation for the growing adoption of induction heating systems.

Whether used to forge high-strength engine components, braze critical braking parts, or cure coatings and adhesives, induction heating plays a crucial role in modern vehicle production. It supports the industry’s goals of developing lighter, more durable, and energy-efficient vehicles—all while streamlining operations and lowering manufacturing costs.

Induction heating works by using electromagnetic fields to generate heat directly within electrically conductive materials—such as the metal components commonly used in automotive manufacturing.

When a conductive object, like a steel rod, is placed inside a high-frequency alternating magnetic field, circulating eddy currents are induced within the material. These currents produce heat through electrical resistance, allowing for rapid and precise temperature control. Unlike traditional methods that rely on external heating elements or radiant heat sources, induction heating delivers energy directly into the workpiece itself.

· Induction coils can quickly raise the temperature of a targeted area, often reaching brazing or forging temperatures in just a few seconds.

· The process is highly localized, applying heat only where it's needed—reducing thermal stress on surrounding areas and preserving part integrity.

· Since only the intended workpiece is heated—not the environment or tooling—induction heating offers excellent energy efficiency and lower operating costs.

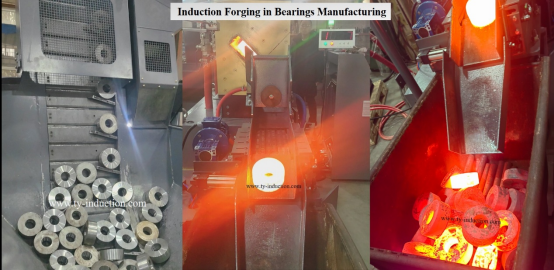

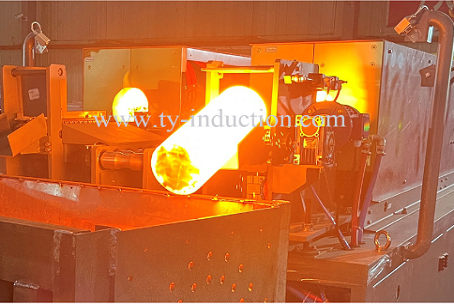

Automotive Manufacturing Applications: Forging and Forming

In the production of engine and drivetrain components, raw parts often begin as metal billets or pre-forms that must be heated to extremely high temperatures before shaping.

While gas-fired and electric furnaces were traditionally used for this preheating stage, induction heating is now widely adopted due to several key performance advantages:

· Precise Thermal Control: Induction systems allow manufacturers to heat specific sections of a billet with great accuracy, rapidly achieving forging temperatures—often exceeding 1,000°C for steel components.

· Reduced Oxidation: Faster heating cycles minimize the formation of oxide scale on the metal surface, which reduces waste and improves the surface finish of finished parts.

· Higher Throughput: With significantly shorter cycle times, induction heating supports the fast-paced production needs of today’s automotive industry, increasing output without compromising quality.

These benefits make induction heating ideal for applications such as crankshaft forging, gear blank heating, and suspension component forming—where consistent, repeatable results are essential.

Induction heating is also widely used in the brazing of critical automotive components such as brake calipers, fuel injectors, and transmission assemblies. Its ability to deliver uniform heat to joint areas ensures strong, reliable bonds without overheating adjacent materials.

Compared to flame or furnace brazing, induction provides:

· Faster, more consistent heating

· Reduced risk of distortion or damage

· Better repeatability for automated lines

This makes it especially valuable in high-volume production environments where quality and efficiency are top priorities.

Curing Coatings and Adhesives

Beyond metalworking, induction heating plays a vital role in curing adhesives and coatings used in automotive assembly. This includes structural bonding of body panels, adhesive curing in electric vehicle battery packs, and powder coating treatments.

Because induction can heat metal substrates rapidly and uniformly from within, it significantly shortens curing times and enhances bond strength—without damaging sensitive surrounding materials like plastics or electronics.

Environmental and Economic Benefits

As the automotive sector moves toward greener manufacturing practices, induction heating aligns well with sustainability goals. It produces fewer emissions than combustion-based heating, consumes less energy, and eliminates the need for hazardous fuels.

From an economic standpoint, the technology helps reduce scrap rates, increase line speeds, and lower long-term maintenance costs—making it a smart investment for forward-thinking manufacturers.

Induction heating is driving innovation across the automotive industry by offering unmatched speed, precision, and efficiency. From forging and brazing to adhesive curing and beyond, it enables automakers to build better vehicles at lower costs and with less environmental impact.

As production demands evolve and new materials enter the market, induction heating will continue to play a central role in shaping the future of automotive manufacturing.

Transform Your Production Line with TY INDUCTION Precision Induction Heating Solutions – Faster, Cleaner, and More Efficient Than Ever Before.

Hot Products

Contact Us

Enquiry hotline:

+86 135 4128 7190

Email:

Address:

No.18,14th Floor, Building 2, No. 169 Zhongli Road, Banzhuyuan Subdistrict, Xindu District, Chengdu, Sichuan, China, Code:610000

Related Products