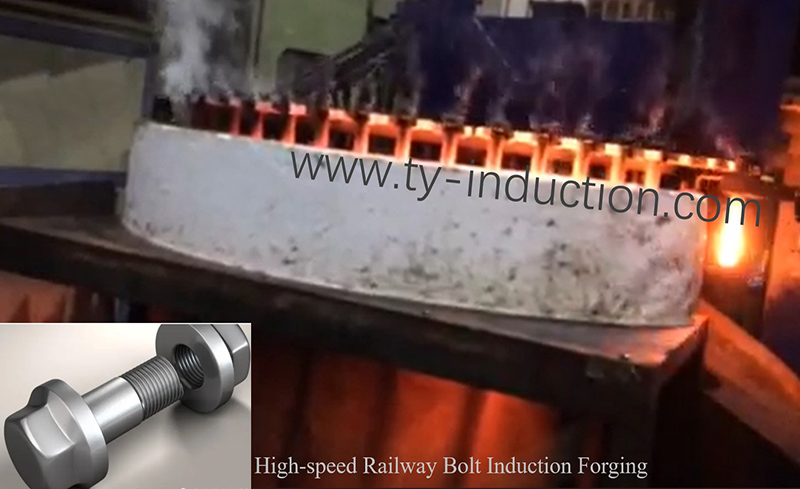

High-speed Rail Bolts Forging

Compared with ordinary trains, high-speed trains have higher requirements for driving safety, which requires more reliable bolts that can effectively prevent falling off. Therefore, the forging requirements for high-speed rail bolts are also extremely high, and Induction Heating can ensure the forging quality of high-speed rail bolts.

Compared with ordinary trains, high-speed trains have higher requirements for driving safety, which requires more reliable bolts that can effectively prevent falling off. Therefore, the forging requirements for high-speed rail bolts are also extremely high, and Induction Heating can ensure the forging quality of high-speed rail bolts.

Since the hot forging process is carried out at high temperature, High-speed Rail Bolts Forging by induction heating / Induction Forging has the following advantages:

l The induction heating temperature can be controlled.

l Forgings at high temperature have good plasticity

l Low deformation resistance and easy to form

l Hot forging is suitable for various materials

l Especially suitable for processing large size bolts / nuts and special-shaped parts

l Hot forging is especially good for extra-long and extra-short bolts

l Hot forging avoids the problems of difficult forging, easy cracking and low yield of cold heading of alloy steel and stainless steel.

l Hot forging has good forming performance and small forging force.

Photos

Hot Products

Contact Us

Enquiry hotline:

+86 135 4128 7190

Email:

Address:

No.18,14th Floor, Building 2, No. 169 Zhongli Road, Banzhuyuan Subdistrict, Xindu District, Chengdu, Sichuan, China, Code:610000

HOT NEWS

How Does the Induction Hardening Process Increase the Hardness of Steel?

April 30, 2025

How Quenching and Tempering Line was Produced and delivered?

April 29, 2025

Is Tempering Required After Induction Hardening?

April 18, 2025