Everything You Should Know Before Buying an Induction Heat Treatment Machine: 10+ Key Questions

May 20, 2025

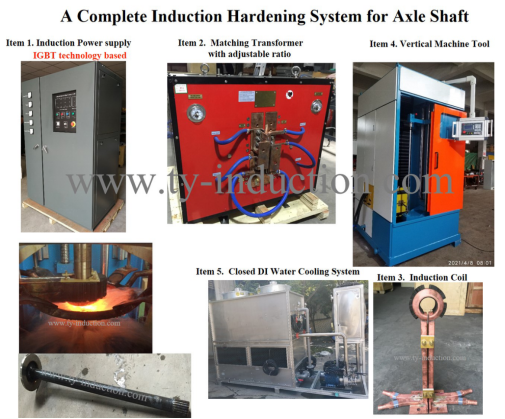

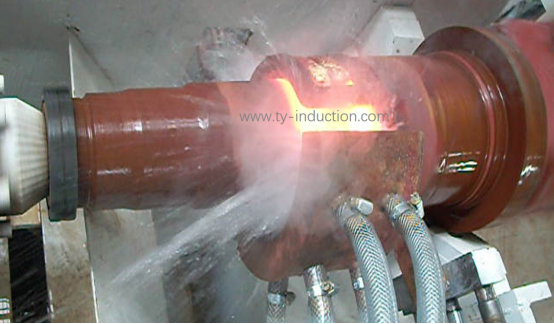

Purchasing induction heat treatment machines is more than just an investment in equipment. It is a strategic decision that can affect the quality, efficiency and profitability of your entire production line. Whether you are manufacturing axles, gears, rods, tubes or suspension components, induction heating can provide speed, precision, energy efficiency and consistency that traditional heating methods cannot match.

Yet, there are a wide variety of options on the market—different power ratings, frequencies, coil designs, levels of automation, and price points. So how do you choose the right induction heat treatment machines for your production?

Here are the most critical questions you need to ask (and answer) before investing in an induction heat treatment system for your automotive or industrial application.

Different metals have different responses to induction heating:

· Steel (especially carbon and alloy steels) is highly responsive.

· Stainless steel needs special frequency tuning.

· Aluminum and copper require higher frequencies due to lower resistivity.

Match your machine’s frequency and coil design with the specific material to achieve optimal heat penetration and uniformity.

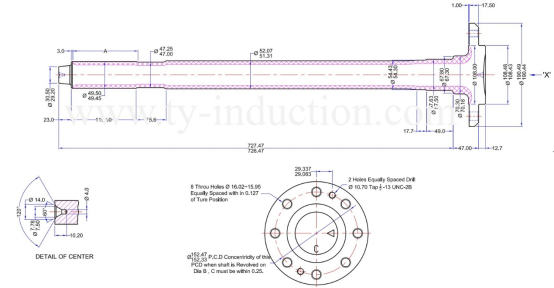

The shape, size, and complexity of your parts will affect:

· Coil design (round, U-type, internal/external)

· Heating time

· Power requirements

Large components like axles or crankshafts may need medium-frequency, high-power systems, while smaller precision parts may require high-frequency, lower power setups.

Different applications require different induction processes:

· Surface hardening (common in gears, shafts)

· Tempering (after hardening to relieve stress)

· Annealing (softening for machining)

· Brazing (joining metal parts)

· Forging or pre-heating

Clarify your exact requirement to choose the correct frequency, coil design, and power rating.

4. What Is the Required Heating Depth and Cycle Time?

Induction heating allows very precise control over:

· Heating depth (surface vs deep hardening)

· Heating rate (speed vs penetration)

These are determined by:

· Frequency (higher frequency = shallower heating)

· Power (more power = faster heating)

Optimize the system for your production cycle time while maintaining metallurgical quality.

General guidelines:

· 1–30 kHz (medium-frequency): for large parts, deep hardening (shafts, crankshafts)

· 100–500 kHz (high-frequency): for surface hardening, smaller parts (gears, fasteners)

· >500 kHz (very high-frequency): for thin, high-conductivity parts (copper, aluminum)

Always consult with the manufacturer for a power/frequency simulation.

In a competitive manufacturing setup, flexibility and automation matter.

Ask:

· Can it be integrated into a robotic/automated line?

· Can coil changes or adjustments be done quickly?

· Can it support multiple recipes or product sizes?

Scalable designs save cost in the long term and grow with your production needs.

Energy savings are one of induction heating's biggest advantages—but not all machines are equal.

Ask about:

· Energy conversion efficiency

· Cooling system efficiency

· Power loss in cables/coils

Choose a system with energy monitoring, smart heating controls, and efficient power converters.

Induction systems generate intense heat—not just in the parts, but also in the coils and electronics.

Ask:

· Is it air-cooled, water-cooled, or chiller-based?

· Is the cooling system integrated or external?

· What maintenance does it require?

A reliable and easy-to-maintain cooling system ensures long equipment life and stable operation.

Induction equipment can pose electrical, thermal, and mechanical risks.

Ask about:

· Overload protection

· Water flow and temperature sensors

· Emergency stop systems

· Safety interlocks

Prioritize systems that are CE/ISO certified and designed with operator safety in mind.

Support doesn’t end after delivery. You’ll need:

· Process development help

· Operator and maintenance training

· Troubleshooting and repair support

Choose suppliers who provide local service, online/remote support, and detailed manuals and videos.

Beyond the initial machine price, consider:

· Energy consumption

· Coil wear and replacement

· Maintenance costs

· Spare part availability

· Operator training needs

Request a detailed lifecycle cost estimate to evaluate ROI accurately.

Before you commit, verify:

· Has the supplier worked with similar applications or industries?

· Can they provide test heating trials or case studies?

· Is there a demonstration unit or reference client?

Real-world success stories are the best proof of capability.

Ask:

· How long does manufacturing and delivery take?

· Is there a warranty (typically 12–24 months)?

· What happens in case of part failure?

Avoid unnecessary downtime with a vendor that offers transparent timelines and strong post-sales support.

Modern factories need connected systems.

Look for:

· HMI with real-time monitoring

· Data logging (temperature, cycle count)

· Remote diagnostics

· SCADA, MES compatibility

Digital capabilities improve process transparency, predictive maintenance, and traceability.

Factor | What to Evaluate |

Materials | Steel, aluminum, copper compatibility |

Part Types | Shafts, rods, tubes, gears |

Heat Process | Hardening, tempering, annealing, brazing |

Frequency & Power | Based on depth and speed |

Coil Design | Custom or modular for fast changeover |

Integration | Robotic line, conveyor, automation-ready |

Energy Use | kWh/cycle, energy-saving controls |

Cooling | Built-in or external; easy maintenance |

Safety | Sensors, overload protection, interlocks |

TCO | Beyond price—include operation, maintenance |

Support | Local + remote + training + documentation |

Customization | Recipes, adjustable parameters, upgrade path |

Proof | Trials, test runs, references |

Warranty | At least 1 year, with service SLA |

An induction heat treatment machine can revolutionize your metal processing capabilities—if chosen correctly. Don’t just look at specs. Think about:

· Your product types and materials

· Your line integration needs

· Your quality and throughput goals

· Your long-term cost and support

By asking the right questions and collaborating with a trusted manufacturer, you’ll ensure maximum performance, minimal downtime, and the best return on investment.

At TY INDUCTION , we understand that choosing the right induction heat treatment machine can be overwhelming—with so many variables like material types, part geometry, frequency, power, automation, and cost to consider. That’s why we don’t just sell machines—we deliver tailored solutions. From free process testing and coil customization to energy-efficient systems and full after-sales support, TY INDUCTION helps you eliminate every concern outlined above. Whether you're heat-treating axles, rods, gears, or complex components, we provide reliable, high-performance equipment that fits your production and budget—perfectly. Let TY INDUCTION simplify your decision and power your next level of manufacturing efficiency.

Hot Products

Contact Us

Enquiry hotline:

+86 135 4128 7190

Email:

Address:

No.18,14th Floor, Building 2, No. 169 Zhongli Road, Banzhuyuan Subdistrict, Xindu District, Chengdu, Sichuan, China, Code:610000

Related Products