Under the Trend of Lightweight Design, the Upgrading of Heat Treatment Technology Is Inevitable for Motorcycle Manufacturers

December 31, 2025

As the global motorcycle industry accelerates toward lightweight design, higher performance, and stricter emission standards, manufacturers are being forced to rethink not only materials and structures, but also the manufacturing technologies behind critical components. Lightweighting is no longer a styling or cost-driven option—it has become a core engineering strategy affecting fuel efficiency, power-to-weight ratio, handling performance, and regulatory compliance.

Under this trend, one conclusion is becoming increasingly clear: traditional heat treatment methods are no longer sufficient to meet the precision, efficiency, and sustainability requirements of modern motorcycle manufacturing. The upgrading of heat treatment technology is not optional—it is inevitable.

This article explores why lightweight design is reshaping heat treatment requirements, what challenges motorcycle manufacturers face with conventional processes, and how advanced solutions such as the Induction Heating Systems are becoming essential in next-generation production lines. The focus is on practical manufacturing realities, long-term competitiveness, and technology-driven decision-making.

Lightweight design in motorcycles goes far beyond reducing overall mass. It is a system-level optimization strategy that impacts nearly every component, including:

· Crankshafts and camshafts

· Gears and transmission shafts

· Connecting rods

· Frame joints and structural reinforcements

· Axles, sprockets, and bearing seats

Manufacturers are increasingly adopting:

· High-strength alloy steels

· Advanced aluminum alloys

· Thin-wall structures

· Hollow or optimized geometries

While these materials and designs reduce weight, they also place much higher demands on heat treatment accuracy and consistency.

Lightweight components typically operate under higher stress concentrations due to reduced material cross-sections. This creates several manufacturing challenges:

· Surface hardness must increase without sacrificing core toughness

· Distortion control becomes more critical

· Heat-affected zones must be precisely managed

· Mechanical properties must be localized rather than uniform

Traditional heat treatment methods often struggle to deliver this level of control, especially at scale.

Conventional heat treatment technologies such as carburizing furnaces, batch quenching, and flame hardening have served the industry for decades. However, in the context of lightweight motorcycle design, their shortcomings are increasingly evident.

Furnace-based processes heat entire components, even when only specific areas require strengthening. This leads to:

· Unnecessary energy consumption

· Increased risk of deformation

· Unwanted changes in microstructure

For thin-walled or precision components, this can result in unacceptable dimensional variation.

Traditional systems lack the ability to:

· Selectively harden complex geometries

· Adjust parameters dynamically for different models

· Integrate easily into flexible production lines

As motorcycle manufacturers expand product lines and shorten model cycles, this rigidity becomes a bottleneck.

Batch heat treatment processes often involve:

· Long heating and soaking times

· High energy consumption

· Large floor space requirements

· Increased work-in-progress inventory

These factors directly conflict with lean manufacturing and just-in-time production strategies.

Lightweight design is not simply about reducing mass—it is about achieving the optimal balance between strength, durability, and fatigue resistance.

Heat treatment plays a decisive role in:

· Enhancing wear resistance on contact surfaces

· Improving fatigue life under cyclic loading

· Maintaining impact resistance and safety margins

Without precise heat treatment, lightweight components may meet weight targets but fail in real-world operating conditions.

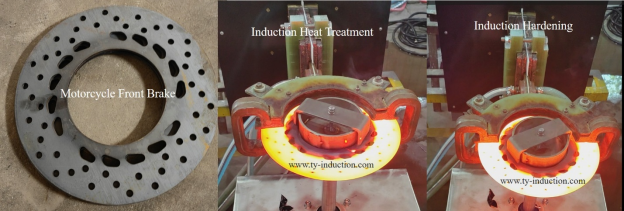

The Induction Heating Systems has emerged as a highly effective solution for addressing the challenges posed by lightweight motorcycle components.

Unlike conventional methods, induction heating uses electromagnetic fields to generate heat directly within the material, enabling highly controlled and localized treatment.

One of the most critical advantages of an Induction Heating System is its exceptional precision.

Key benefits include:

· Selective hardening of specific zones (gear teeth, bearing surfaces, shafts)

· Minimal heat penetration into non-critical areas

· Reduced risk of warping and distortion

· Consistent repeatability across batches

This precision allows manufacturers to confidently use thinner sections and optimized geometries without compromising reliability.

Modern lightweight motorcycles increasingly rely on high-performance alloy steels and specialized materials that require tightly controlled thermal cycles.

Induction heating enables:

· Rapid heating rates tailored to material properties

· Accurate temperature control for complex alloys

· Stable metallurgical structures

· Improved surface-to-core property gradients

This compatibility makes induction technology ideal for next-generation motorcycle powertrain and transmission components.

Lightweight design is often paired with sustainability goals. Heat treatment technology must align with these objectives.

An Induction Heating System offers:

· Significantly lower energy consumption

· Reduced CO₂ emissions compared to furnace processes

· Faster heating with less thermal loss

· Cleaner working environments

For manufacturers facing rising energy costs and environmental regulations, these advantages translate directly into long-term operational resilience.

Induction heating supports continuous and automated production, which is increasingly important in modern motorcycle factories.

Manufacturing benefits include:

· Shorter heating and cooling cycles

· Seamless integration with CNC machining and assembly lines

· Reduced work-in-progress inventory

· Higher overall equipment efficiency (OEE)

This enables manufacturers to respond more quickly to market demand while maintaining quality consistency.

As component walls become thinner, distortion tolerance becomes smaller.

Induction heating minimizes distortion by:

· Heating only the required area

· Reducing overall thermal stress

· Allowing immediate quenching at controlled locations

This significantly reduces post-treatment machining and scrap rates, improving yield and cost efficiency.

Fatigue performance is one of the biggest concerns in lightweight motorcycle design.

Properly applied induction heat treatment can:

· Improve surface compressive stress

· Enhance resistance to crack initiation

· Extend service life under high-frequency load cycles

This is especially important for high-speed motorcycles and performance-oriented models.

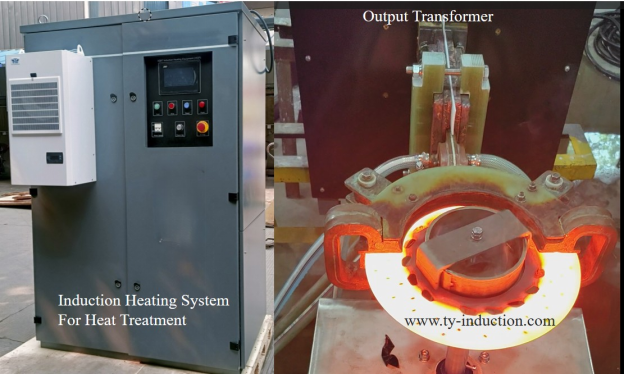

Modern Induction Heating System solutions are typically equipped with:

· Digital power control

· Temperature feedback systems

· Recipe-based parameter management

· Data traceability for quality assurance

This level of control supports standardized global production and compliance with increasingly strict quality requirements.

Traditional flame hardening and batch heat treatment often depend heavily on operator experience.

Induction heating reduces this dependency by:

· Automating process parameters

· Ensuring repeatable results

· Lowering the risk of human error

This is particularly valuable as manufacturers face skilled labor shortages in many regions.

While advanced heat treatment systems require upfront investment, the long-term economic benefits are substantial:

· Lower energy costs

· Reduced scrap and rework

· Higher throughput

· Less post-processing

· Improved product reliability and brand reputation

For manufacturers pursuing lightweight design, heat treatment upgrades deliver measurable ROI over time.

In today’s motorcycle market, performance differentiation increasingly depends on manufacturing excellence rather than visible features alone.

Manufacturers that upgrade heat treatment technology are better positioned to:

· Launch lightweight models faster

· Meet global quality standards

· Adapt to new materials and designs

· Sustain long-term innovation capability

Heat treatment is no longer a background process—it is a strategic capability.

The trend toward lightweight motorcycle design is irreversible, driven by performance expectations, regulatory pressures, and consumer demand. As components become lighter, thinner, and more complex, the limitations of traditional heat treatment methods become increasingly apparent.

Upgrading heat treatment technology is not merely an efficiency improvement—it is a fundamental requirement for enabling modern motorcycle design. With its precision, energy efficiency, flexibility, and compatibility with advanced materials, the Induction Heating System stands out as a key enabler of this transition.

TY INDUCTION empowers motorcycle manufacturers with advanced Induction Heating System solutions that drive lightweight innovation, manufacturing precision, and sustainable performance.

Hot Products

Contact Us

Enquiry hotline:

+86 135 4128 7190

Email:

Address:

No.18,14th Floor, Building 2, No. 169 Zhongli Road, Banzhuyuan Subdistrict, Xindu District, Chengdu, Sichuan, China, Code:610000

Related Products