Why Choose TY Induction's Induction Fusion Sample Preparation Machine for XRF Analysis?

June 25, 2025

The sample preparation process of X-ray fluorescence (XRF) analysis is the process of converting the received sample into a sample suitable for measurement on the machine through appropriate methods. Sample preparation is the most important factor affecting the final accuracy of all X-ray measurements. When using wavelength dispersive X-ray fluorescence (WDXRF) spectrometers for sample analysis, more than half of the errors are caused by sample preparation. Since XRF analysis is non-destructive, there are many preparation methods for different types of samples. The quality of the preparation method is an important factor in determining the accuracy of the analysis.

The reason why Induction Fusion Equipment is selected for sample preparation in XRF analysis is mainly based on its advantages in Efficiency, Homogeneity control, Accuracy Guarantee and applicability. The specific reasons are as follows:

1. Fast and uniform heating

Induction fusion uses a high-frequency electromagnetic field to directly act on crucible to achieve rapid and uniform heating of the material, avoiding the heat conduction delay problem of electric resistance heating, and significantly reducing local overheating or unmelted issues of electric resistance heating.

2. Precise Temperature Control

The melting temperature and time can be precisely controlled to meet the differentiated melting requirements of different minerals (such as iron ore and bauxite) and ensure the completeness of the reaction.

1. Create Uniform Glass Disk

Induction fusion allows the sample to fully react with borate flux to produce a smooth, bright and transparent glass disk, completely eliminating the particle size effect, mineral effect and inter-element absorption enhancement effect, greatly improving the accuracy and reproducibility of XRF analysis,

2. Compatible with Complex Matrix Samples

It is suitable for samples with complex components such as ore, slag, cement, polymer, soil, etc., especially for trace elements (such as Mn, Zn, Cu, etc.) in geological samples. Results are highly consistent with the ICP-AES method and meet the requirements of industry specifications.

· Wide Applications: Covering the fields of mining, metallurgy, building materials (cement/glass), chemical industry and scientific research, it supports efficient sample preparation of various phases such as sulfides, oxides, silicates, etc.

TY-2MC: 1 fusion +1 molding (manual casting)

TY-2AC: 1 fusion +1 molding (auto casting)

TY-4MC: 2 fusion +2 molding (manual casting)

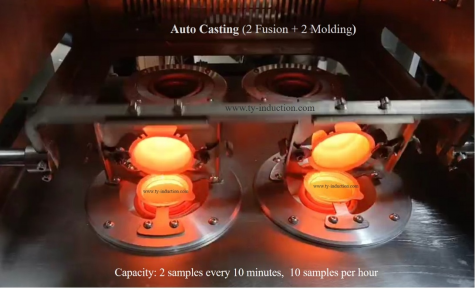

TY-4AC: 2 fusion +2 molding (auto casting)

TY-8MC: 4 fusion +4 molding (manual casting)

TY-8AC: 4 fusion +4 molding (auto casting)

TY-4MFA: 2 fusion +2 molding (auto casting); Simply touch a button on panel to select sample preparation for XRF, ICP or AA analysis

TY-NFM: Specially designed for sample preparation for XRF spectrometer and direct reading spectrometer, especially for sample preparation of non- ferrous metals such as copper, aluminum and zinc

TY-MRM: Metal Sample Preparation Machine (centrifugal casting)

In just 30 seconds, the material can be heated from room temperature to 1200°C.

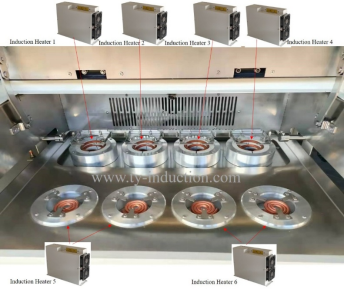

Each fusion position is equipped with independent induction heater and coil. For example, the TY-8MC model has four (4) induction heaters & coils for fusion heating and two (2) induction heaters & coils for molding heating.

Automated design can process multiple samples in batches, improving overall efficiency. 10 minutes per cycle, up to 20 samples can be prepared per hour

6.1. Molds and Crucibles holders are made of superior quality temperature-resistant alloy to ensure a service life of up to 10 years

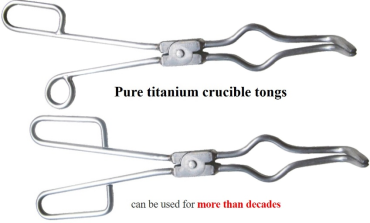

6.2. TY Induction offers pure titanium tongs to replace platinum-coated pliers. A pair of tongs can be used for more than decades, saving the re-platinum-coated repair cost of platinum-coated tongs.

During the fusion process, the molten mixture is always agitated horizontally and centrifugally to ensure that materials are fully mixed and guarantee the homogeneity of samples.

Closed working chamber avoids the risk of open flames (gas heating) or high temperature radiation, while the automatic casting design eliminates contact with hot materials and surfaces for enhanced safety and really cold-to-cold operation.

TY Induction's Induction Fusion Sample Preparation Machine has a one-touch operation feature and a wide range of predefined fusion program (15) that avoids deviation or contamination caused by manual operation and ensure sample preparation standardization.

Built-in exhaust system removes waste gas.

Induction Fusion has become the preferred method for preparing high-precision glass disks in XRF analysis due to its efficient and uniform heating characteristics, excellent matrix effect elimination ability, high-precision automatic control and wide applicability, especially for scenes with complex composition or strict quantitative analysis requirements.

Hot Products

Contact Us

Enquiry hotline:

+86 135 4128 7190

Email:

Address:

No.18,14th Floor, Building 2, No. 169 Zhongli Road, Banzhuyuan Subdistrict, Xindu District, Chengdu, Sichuan, China, Code:610000

Related Products