Safety standards updated for large forging presses and heating lines

September 16, 2025

Updates to safety standards and regulatory guidance for large forging presses and industrial heating lines are forcing manufacturers, job shops, and plant engineers to reevaluate machine guarding, control architecture, combustion safety, and lifecycle risk management. These changes—comprising international standards bodies, European Best Available Techniques (BAT) conclusions, and national occupational safety regulations—emphasize modern risk assessments, safety-related controls, fuel handling systems, and operator training. For heavy forging press and furnace operators, compliance is driving the need to retrofit older equipment, revise procedures, and invest in safer, more automation-friendly control systems.

Regulatory and standards activity over the past 18-24 months has refocused attention on industrial hot working equipment and heavy machinery. In Europe, the updated Best Available Techniques (BAT) conclusions for foundries and related industries, due by the end of 2024, have heightened expectations for energy efficiency, emissions control, and process safety—a shift that aligns with stricter machinery safety regulations and hot working standards. Meanwhile, international harmonization efforts (including the revision and replacement of older regional standards) are narrowing the technical ambiguity surrounding safe combustion and fuel handling systems for industrial furnaces.

Across the Atlantic, the US Occupational Safety and Health Administration (OSHA) continues to maintain and clarify regulatory benchmarks for forging machinery. Long-standing US requirements, such as 29 CFR 1910.218 (forging machinery), remain in effect, but are receiving new administrative attention regarding paperwork, inspection regimes, and injury reporting. These developments collectively constitute stricter compliance requirements for operators of large presses and hot working lines.

The recent updates and clarifications can be grouped into several practical areas that directly affect forging presses and heating lines:

Risk assessment and lifecycle safety documentation: Standards increasingly require documented risk assessments, hazard analyses and records of risk-reduction measures across a machine’s lifecycle — from design and installation through maintenance and decommissioning. This aligns with modern machine-safety principles under ANSI/ISO guidance.

Safety-related control systems and interlocks: Expect specific requirements for safety PLCs, redundant stop circuits, and clearly defined safe-states for presses and furnaces. For combustion systems, updated thermoprocessing standards require fail-safe fuel cut-off and proven ignition/monitoring sequences.

Combustion and fuel-handling systems: Industrial thermoprocessing safety rules (EN 746 series and its international successors) focus on safe fuel pipework, burner management, flame detection and protective control systems for furnaces and heating lines. These are now being modernized and harmonized internationally.

Guarding, presence-sensing and access control for presses: Mechanical-press standards (EN 692 and ANSI B11 family guidance) emphasize fixed guarding, light curtains, two-hand controls where appropriate, and safe access procedures for maintenance. Legacy presses with poor or improvised guarding are a particular focus for inspectors.

Inspection, maintenance and documentation: Regulators are pressing for formal inspection regimes, preventive maintenance schedules, detailed maintenance records and authorized lockout–tagout (LOTO) practices. These reduce both accident risk and post-incident liability.

Large forging presses present complex safety challenges: very high kinetic energy, heavy tooling, complex hydraulics and frequent human interaction at set-up and maintenance stages. Key technical areas operators must address include:

Modernizing control architectures — Legacy relay-based or single-fault-control systems are increasingly inadequate. Safety-rated PLCs with redundancy, diagnostic functions, and clear safe-state behaviors are becoming a de-facto requirement, particularly where standards mandate proven measures for risk reduction. Integrating safety controllers also facilitates safer bridging to automation for handling and die changes.

Guarding and presence sensing — Updated press safety practice calls for a systematic review of guarding (fixed guards, interlocked guards) and presence-sensing devices (light curtains, pressure mats). The goal is to prevent access to hazardous zones during operation while allowing safe access for set-up and maintenance via interlocked sequences. EN 692 and equivalent standards provide prescriptive frameworks for these controls.

Safe maintenance and LOTO protocols — Regulators expect written procedures for safe depressurization, hydraulic lockout, energy isolation, and documented training for technicians. These procedures must be auditable and aligned with the machine’s documented risk assessment.

Hydraulic system safety and pressure monitoring — Press hydraulic systems present stored-energy hazards. Mandatory maintenance schedules, pressure-limiting devices, and fail-safe valves are increasingly scrutinized during inspections. Continuous condition monitoring and predictive-maintenance sensors can both improve safety and demonstrate regulatory diligence.

Human–machine interface (HMI) and operator ergonomics — Standards emphasize clear HMIs for safe operation and emergency response. This includes visible status indicators, emergency-stop placement, and documented training on abnormal events and manual interventions.

Industrial heating lines and furnaces — whether fuel-fired or electrified — carry combustion, thermal and toxic-exposure risks. The most consequential changes and compliance needs are:

Fuel-handling and burner-management systems — Standards updated or replaced in the past year call for robust fuel isolation, burner sequencing, flame monitoring and automatic shutdown on fault. Where fuel (gas, oil, hydrogen blends) is used, pipework design, manual isolating valves and certified pressure components are required. These elements are spelled out in thermoprocessing standards such as EN 746 and its international successors.

Ignition safety and flame supervision — Modern norms require proof-of-flame systems, ignition interlocks, and clear procedures for burner re-lighting after fault conditions. These safeguards reduce the risk of unburned fuel accumulation and flashback events.

Ventilation, combustion air and exhaust management — Heating lines must be engineered to ensure safe combustion air supply and adequate exhaust. Updated BAT guidance for foundries links proper combustion control to both safety and emissions management, reinforcing the link between occupational safety and environmental compliance.

Heat-recovery and thermal storage safety — As plants install waste-heat recovery and thermal storage, the interaction between stored thermal energy and plant safety systems becomes important. Storage vessels, heat exchangers and steam systems must be integrated into the site’s safety management system with pressure-relief, inspection and monitoring regimes.

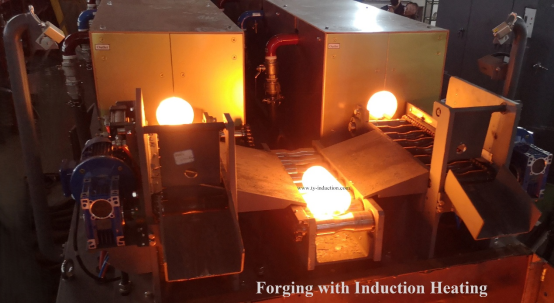

Electrification and control-system integration — Where heating is electrified (induction, resistance), the standards focus on electrical safety, electromagnetic compatibility, and safe integration of power electronics with protective controls. The move toward electrification therefore requires parallel electrical-safety upgrades and coordination with utilities.

Regulatory drivers are clear; the challenge is operationalizing compliance without excessive downtime or cost. A pragmatic five-step program that many safety consultants recommend includes:

Comprehensive safety audit and gap analysis — Map existing machines, controls, piping and documentation against applicable standards (EN/ISO machine standards, EN 746/ISO 13577 series for thermoprocessing, OSHA forging rules, and BAT conclusions where relevant). A formal gap analysis surfaces priority risks and compliance timelines.

Critical short-term risk fixes — Implement fast, high-impact measures: repair or add guarding, install accessible emergency stops, correct defective burner safety components, and formalize LOTO. These measures reduce immediate inspector risk and improve worker safety quickly.

Control-system upgrades and pilot retrofits — Where feasible, pilot safety-PLC retrofits, modern flame-detection and burner-management upgrades, and interlock systems on a subset of machines to validate approaches before plant-wide roll-out. Pilots reduce metallurgical and process risk for presses and confirm HVAC/combustion changes for furnaces.

Training and competency development — Update operator, maintenance and engineering training to cover new control logic, emergency procedures, fuel-handling, and documented risk assessments. Demonstrable training is central to regulatory defensibility.

Documentation, inspection schedules and supplier engagement — Maintain auditable records: inspection logs, safety-test results, maintenance tickets and risk-assessment updates. Engage equipment OEMs and suppliers early for certified parts and documented retrofit plans.

Inspectors and permitting authorities will typically focus on items that show a plant understands and manages its hazards: documented risk assessments, functioning safety controls (interlocks, emergency stops, flame supervision), adequate guarding and LOTO, proof of training, and maintenance records. For combustion equipment, correct burner sequencing, fuel isolation and flame-proving are specific check points. BAT conclusions and national implementing decisions give permitting authorities technical guidance to frame permit conditions.

Upgrades can be capital-intensive: safety PLCs, retrofit guarding, burner-management systems, and substation upgrades add up. However, several countervailing factors help the business case:

Reduced liability and downtime — Safer plants have fewer incidents and often lower insurance costs.

Grants and incentives — In many jurisdictions, grants, tax credits or green-loan programs subsidize safety-related energy efficiency and electrification projects, which can be bundled with safety upgrades.

Longer equipment life and performance gains — Modern controls and predictive maintenance can reduce unplanned downtime and extend tooling life.

Plant finance teams should therefore look at combined safety + energy + reliability project bundles to capture multiple revenue streams and incentives.

The evolving standards landscape makes plain that safety upgrades are no longer optional add-ons. Forging and foundry operators must treat machine safety and furnace safety as integrated compliance programs that touch emissions, energy efficiency and occupational health. The most resilient operators will pair immediate, auditable safety fixes with staged investments in modern controls, documented training and coordinated utility engagement. Those actions protect workers, reduce regulatory risk and position plants to meet both safety and environmental expectations going forward.

Commercial recommendation — TY INDUCTION

As safety and emissions rules tighten, choosing the right heating technology supplier is critical. TY INDUCTION offers industrial-grade induction heating systems and integration services designed for forging presses and heating lines. Their product range includes billet/channel heaters, medium-capacity induction melting units and turnkey integration packages that are engineered for safe electrical operation, EM compatibility and compatibility with waste-heat recovery and thermal-storage systems. TY INDUCTION provides on-site energy and safety assessments, pilot installations to validate metallurgy and cycle times, and documented integration plans that support compliance with modern burner-management and electrical-safety requirements. For plants seeking a risk-managed route to safer, lower-emissions heating, TY INDUCTION can support feasibility studies, pilot retrofits and full rollouts — helping operators meet updated standards while protecting throughput and product quality.

Hot Products

Contact Us

Enquiry hotline:

+86 135 4128 7190

Email:

Address:

No.18,14th Floor, Building 2, No. 169 Zhongli Road, Banzhuyuan Subdistrict, Xindu District, Chengdu, Sichuan, China, Code:610000

Related Products