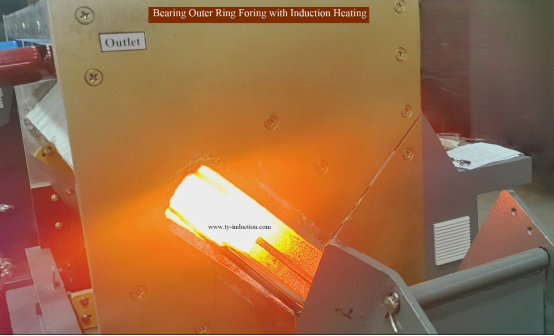

Bearing manufacturer boosts production yield with automated billet induction heating

September 22, 2025

A leading bearing manufacturer recently reported a measurable jump in production yield after installing an automated induction billet-heating line that replaces a mix of manual pre-heating and older gas-fired ovens. The upgrade—part automation, part process re-engineering—reduced cycle variability, cut heating time per billet and improved first-pass forging yield, while also improving shop-floor safety and lowering combustion-related emissions. Early results from pilot and rollouts suggest induction-based, automated billet heating is becoming a pragmatic productivity lever for high-volume cold-and-hot-formed bearing producers.

Bearings are precision parts: dimensional tolerances, controlled microstructure and low scrap rates are core to manufacturing economics. The forging and heat-treatment stages are particularly temperature-sensitive—small deviations in billet temperature at the point of forging can cause flash, incomplete fill, excessive tool wear or metallurgical variability that leads to rework or scrap. Traditionally, many shops have relied on gas ovens, manual handling and operator judgment to heat billets; that creates variability and limits throughput. Modern production lines increasingly treat the billet-Induction Heater as a first-class process-control device rather than a crude oven—automating and electrifying the heating step enables repeatable preheat, faster cycle times and more stable downstream forging performance.

An automated billet heating solution typically combines three elements:

Electrified heating technology (usually induction) — induction coils or induction melting/heating modules rapidly and directly heat the metal workpiece with precise control. Induction heats only the workpiece (not the surrounding air), enabling fast, localized heat-up and excellent repeatability.

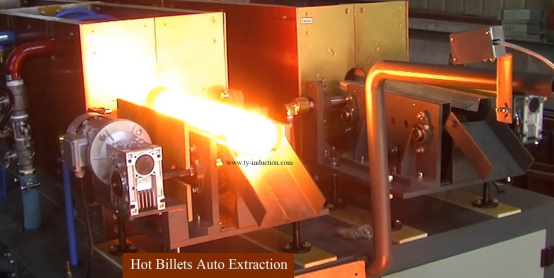

Material handling automation — conveyors, indexers, pick-and-place robots or gantries deliver billets to and from the heater with repeatable positioning and matched timing to the forging press. Automation minimizes manual handling variance and reduces operator exposure to hot parts.

Process control & integration — closed-loop temperature control, PLC/SCADA integration and recipe management ensure each billet receives the exact heating profile required for its alloy and downstream forging schedule. Integration with MES/ERP enables traceability and production analytics.

Together these components transform heating from a batch, operator-dependent step into an inline, deterministic process—reducing temperature spread between billets and shortening cycle time without sacrificing metallurgical quality.

In the pilot cited by the manufacturer, the automated line delivered several measurable gains over the prior manual/gas-oven approach:

Shorter heat-up times: Induction heating allowed the plant to cut billet heating time substantially, freeing capacity at the front end of the forging line and enabling higher press utilization. Case studies show induction can halve heating times versus conventional ovens in many forging applications.

Tighter temperature control: Closed-loop thermocouple or non-contact pyrometer control reduced temperature variance at the point of forging—this led directly to an increase in first-pass accept rate and less corrective machining. Precision heating is frequently cited as a core advantage of induction heating in bearing and precision-forging contexts.

Lower scrap and rework: With more consistent billet temperatures and reduced oxidation (no open flame exposure), the plant saw fewer defective parts and reduced fettling. Reduced scrap improves material yield and lowers per-part cost.

Improved safety and ergonomics: Removing manual hot-part handling and oil-bath or torch pre-heating practices cut operator exposure to high temperatures and eliminated certain contamination risks (e.g., oil spills). Safer lines make it easier to standardize procedures and demonstrate compliance.

These outcomes amount to a step change in bottom-line throughput—more parts produced per shift at lower variable cost per component—especially important in high-volume bearing production where margins are tight and quality standards are high.

Three technical attributes make induction heating particularly well suited to bearing billets:

Rapid, volumetric heating: Induction creates eddy currents inside the metal and heats from within, producing fast, uniform temperature rise that is easier to control than surface or convection heating. This reduces thermal gradients and helps preserve metallurgical properties.

Precise zone control and scalability: Modern induction heaters are modular and can be configured in heating zones that match billet length and required gradients; power, frequency and coil geometry can be tuned for material and cross-section. That adaptability is essential when bearings use different steels or alloys across product families.

High electrical efficiency & low idle losses: Induction heats the part, not the environment—so energy use is concentrated and idling losses are far lower than in large gas ovens that must be kept hot. From a cost and emissions standpoint this can be decisive where electricity is low-carbon or competitively priced.

Automating billet heating is not risk-free. The common challenges and mitigation tactics include:

Metallurgical validation: Changing heating profiles can affect grain structure and forging flow. Mitigation: run metallurgical trials and destructive testing on pilot batches to validate properties before full rollout.

Electrical infrastructure: High-power induction systems may require substation upgrades or stepped power contracts. Mitigation: coordinate early with utilities, explore off-peak tariffs or on-site generation, and consider modular staged rollouts that spread electrical upgrades.

Material handling matching: Conveyors must precisely match furnace dwell time to desired heating profile. Mitigation: use variable-speed conveyors and feedback from temperature sensors to adjust speed in real time.

Thermal process control: Non-contact pyrometers, two-point temperature control and recipe management are required to avoid overheating and overheating-related defects. Mitigation: redundant sensors and interlocks, combined with automated recipe safeguards.

Operator training and safety: Automated lines change operator roles toward supervision and maintenance. Mitigation: invest in training, formal operating procedures and lockout–tagout (LOTO) processes for automated equipment.

When a plant considers automated billet heating, procurement and engineering teams should build a Total Cost of Ownership (TCO) model that includes:

Upfront capital cost of the induction heater(s), coils, automation hardware and control software.

Electrical infrastructure upgrade costs (transformer, cabling, switchgear) and potential utility incentives.

Energy cost per tonne—compare induction electricity use (often 80–90% system efficiency in optimal designs) versus gas oven fuel cost and consider local grid carbon intensity if sustainability targets matter. Labor and safety cost reductions from automation (reduced manual heating, fewer safety incidents).

Productivity gains: shorter cycle time, higher first-pass yield, and lower scrap rates.

Many OEMs and systems integrators support feasibility studies and pilot lines; these pilots are essential to quantify yield improvements before committing to full-scale capital deployment. Several industry case studies show payback windows that are attractive once yield gains and energy savings are included—especially in high-volume, precision component lines such as bearing manufacture.

Beyond yield, automated induction heating can support sustainability and regulatory goals:

Lower direct combustion emissions: Electrified heating eliminates on-site combustion for the heating step, reducing scope-1 emissions where electricity is low-carbon. This helps manufacturers meet corporate net-zero pledges and regulatory emissions targets.

Better energy integration: Induction lines are compatible with waste-heat capture and electrified plant energy management (including battery storage and demand-response), enabling smarter energy use across the site.

Cleaner workplace: Eliminating oil baths, open flames and combustion byproducts improves working conditions and reduces fugitive contamination risks that can affect bearing surface quality.

These sustainability advantages can also be part of the procurement case when customers or tier-one partners require lower product carbon intensity or improved supply-chain traceability.

A staged pilot is the least-risk route to full automation. A recommended pilot roadmap:

Scoping & baseline: Measure current heating time distribution, scrap rates related to heating, energy use and safety incidents.

Feasibility & simulation: Use electromagnetic/thermal simulation tools to model coil geometry and heating zones for the specific bearing billet sizes. Simulations reduce trial & error and accelerate coil design.

Small pilot line: Install a single-lane induction heater with automated feeding and closed-loop temp control on a representative product family. Run metallurgical and dimensional tests.

Evaluate & iterate: Compare first-pass yield, energy use, cycle time and operator feedback. Adjust frequencies, power and conveyor speeds.

Scale & integrate: If pilot targets are met, scale to multi-lane heaters, integrate with MES, and negotiate any needed utility upgrades. Include spare-parts and maintenance plans.

Pilots reduce capital risk and provide documented evidence to financiers or grant programs—in many regions industrial decarbonization funds and efficiency grants favor projects with validated pilots.

To translate pilot success into plant-wide performance, TY INDUCTION offers turnkey induction billet-heating systems and line integration services tailored for bearing manufacturers. TY INDUCTION’s portfolio includes modular billet heaters, automated feeding and extraction systems, and closed-loop temperature control packages engineered to minimize thermal variance and maximize first-pass yield. Their engineering team supports feasibility studies, electromagnetic/thermal simulation, on-site piloting and utility coordination to ensure scalable rollouts. For bearing producers aiming to boost throughput, reduce scrap and improve workplace safety while aligning to sustainability targets, TY INDUCTION provides the technology and project support to make automated billet heating a reliable, ROI-driven reality.

Hot Products

Contact Us

Enquiry hotline:

+86 135 4128 7190

Email:

Address:

No.18,14th Floor, Building 2, No. 169 Zhongli Road, Banzhuyuan Subdistrict, Xindu District, Chengdu, Sichuan, China, Code:610000

Related Products