Technical Breakthrough:a Single Induction Hardening System for Ball Studs and Ball Housings

July 08, 2025

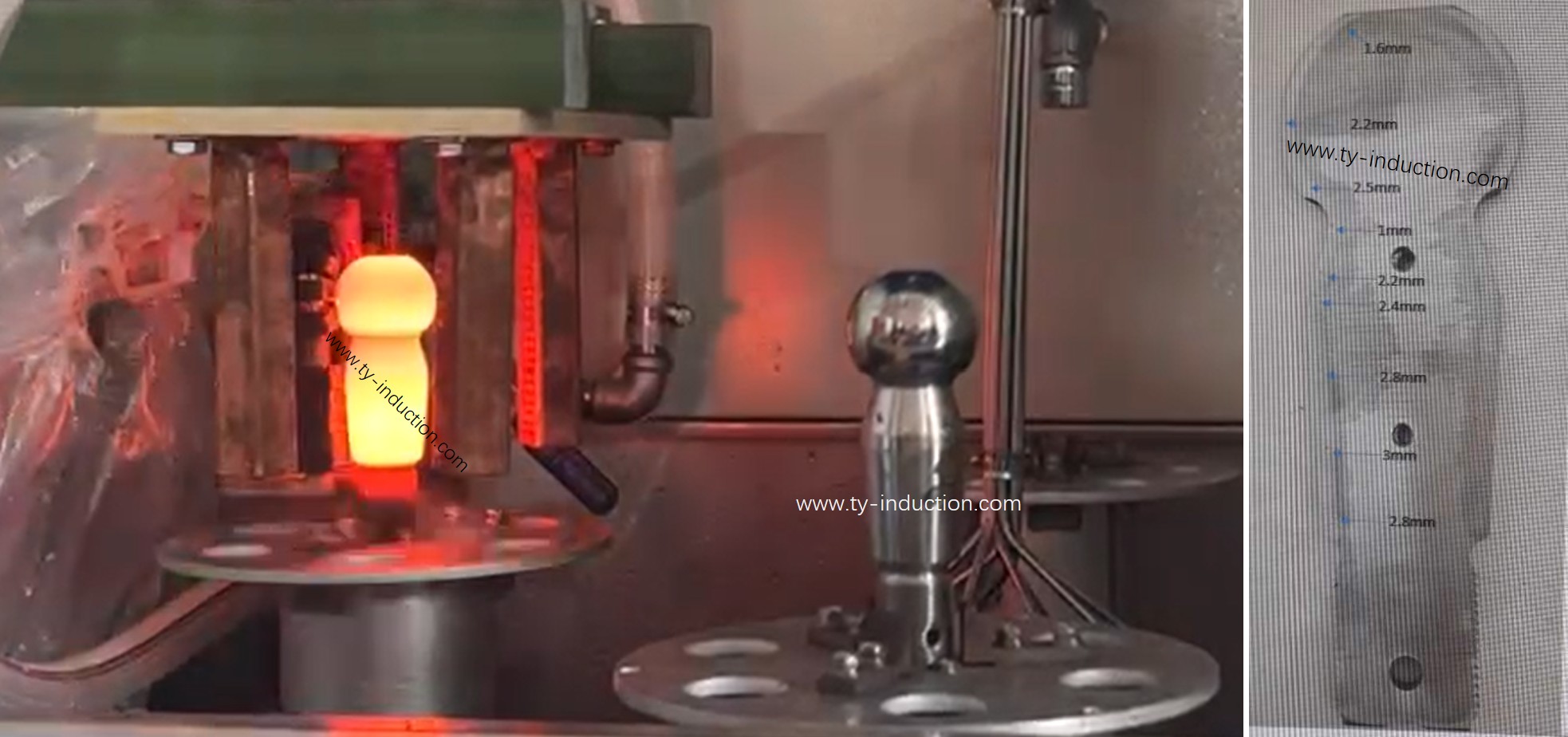

In March 2025, TY INDUCTION officially signed a contract with a Spanish auto parts manufacturer for custom Induction Hardening System. The customer is a well-known European steering system supplier. This order requires the hardening of two complex geometry parts, ball stud and ball housing, to be completed on the same equipment. The process difficulty coefficient is at the leading level in the industry.

· Differences in material properties

The ball pin (material SAE4140) and the ball housing (material SAE1026) have different hardenability, and a dual-mode heating needs to be developed

· Geometric tolerance control

The depth of the spherical hardened layer is required to be ±0.15mm, and the width of the transition zone is ≤1.2mm

· Equipment compatibility

The inductor positioning system needs to be modified based on the existing TYHGP-100 equipment

After continuous technical research and process verification, the project team successfully realized the hardening of two automotive parts, ball studs and ball housings, on a single Induction Hardening Machine. This breakthrough marks a significant improvement in the flexible application capabilities of induction hardening equipment. The specific implementation process is as follows:

3.1. Process development

l Develop a dual-mode heating: progressive scanning heating for the ball stud and one-shot heating for the ball housing

l Develop an adaptive spray system to achieve dynamic adjustment of the cooling rate

3. 2. Innovative design of tooling and fixtures

l Modular positioning system enables rapid switching between two workpieces

l Three-dimensional adjustable induction coil device is compatible with workpieces with different curvature radii

3. 3. Verification test

A total of 27 groups of process tests were conducted, and the final samples:

l Surface hardness: HRC58-62 (meet customer requirements)

l Hardened layer depth: 1.8-3.0mm (meet customer requirements)

4.1. After verifying the test samples, Carlos Mendez, the customer technical director, wrote a letter: "Ok perfect excellent achievement! The microstructure and hardness distribution exceed our expectations, especially the consistency of case depth on spherical surfaces."

4.2. The customer's production director specifically mentioned it in the acceptance report:

· The hardness difference of 50 samples produced continuously is only HRC2.3 (the standard requires HRC4)

· The qualified rate of ball housing inner cavity quenching reached 99.6%, breaking the qualified rate record of 85% of its previous supplier

4.3. The purchasing manager wrote in the email:

· "Your team not only solved the dual-material quenching challenge, but also achieved 18% energy saving compared to our original process. This sets a new benchmark for our global suppliers."

5.1. Equipment utilization rate increased by 40%, saving about 18% of energy consumption

5.2. Reduced dedicated equipment procurement costs (before required Induction Hardening Equipment for ball studs and ball housing separately)

5.3. Product yield increased from 92.6% to 98.4%

5.4. A new breakthrough in processing special-shaped parts with a single device

5.5. Lay a technical foundation for subsequent similar orders in the European market

6.1. Develop AI parameter self-learning system to achieve automatic process matching

6.2. Extend to other complex geometry parts quenching applications (such as universal joint forks)

Hot Products

Contact Us

Enquiry hotline:

+86 135 4128 7190

Email:

Address:

No.18,14th Floor, Building 2, No. 169 Zhongli Road, Banzhuyuan Subdistrict, Xindu District, Chengdu, Sichuan, China, Code:610000

Related Products